Assembly Line Balancing

History of Assembly Lines

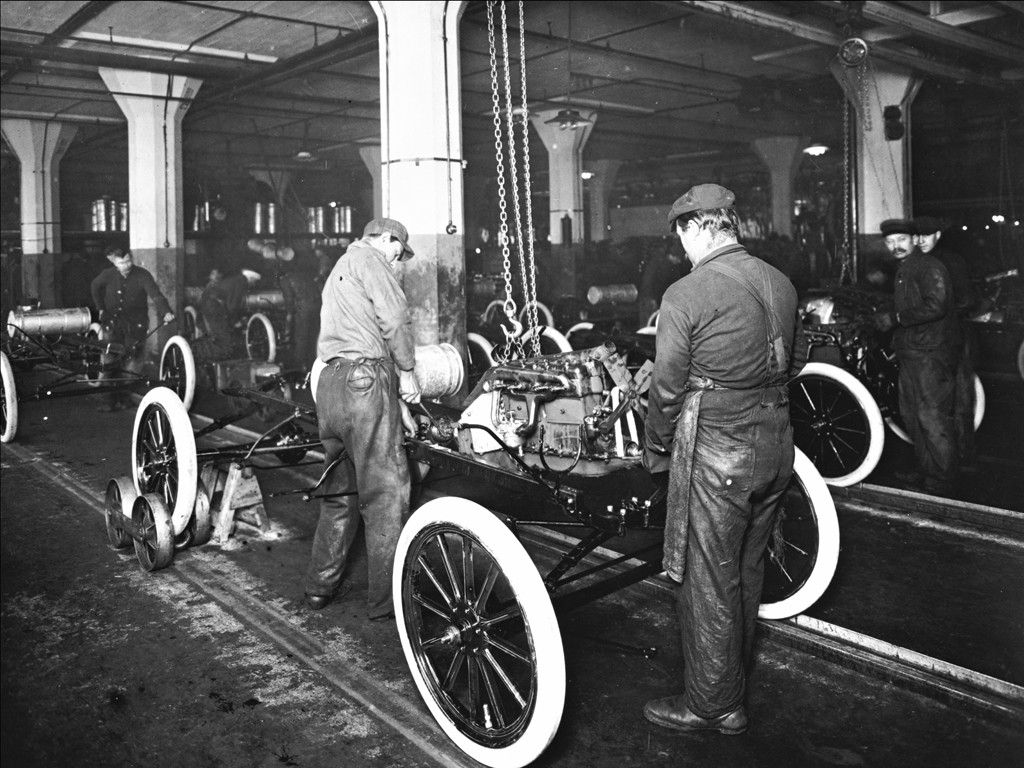

Introduced in 1908, the Ford’s Model T was simple, hard and inexpensive. Regarding Ford, the man who decided to build motor cars for the great multitude, this model was not enough inexpensive. Ford supposed to build his cars more efficiently in order to sell them more economically.

Henry Ford installed the first assembly line for the mass production of an entire automobile on 1st of December, 1913. This innovation has a great impact on the time required to build the car. The time decreased from 12 hours to one hour and 33 minutes.

What is Assembly Line Balancing?

Assembly Line Balancing Problem is the process of assigning work elements to work stations, without violating precedence relations, in order to attain a certain objective such as minimizing cycle time or minimizing the number of work stations...etc.

Benefits of Assembly Line Balancing:

- Improving Line Efficiency

- Profit maximization or cost minimization

- Saving space

- Minimizing number of workers

Assembly Line Approaches

Assembly line balancing problem is considered as NP-hard problem; where finding an optimal solution is computationally exhausting. Hence, heuristic and meta-heuristics algorithms are developed so as to solve this problem. ALB algorithms are classified as follows:

Exact algorithms

Exact algorithms are used to find the optimal solution based on the enumeration of feasible solutions for the existing problem. Sometimes, we can see that some problems can not be solved due to the exhaustive number of enumerations needed. That is why we use meta-heuristics and heuristics.

Heuristic Algorithms

Heuristic algorithms are those used to solve operation research problems using logical rules like re-arranging of work elements by longest or shortest processing times…etc. These algorithms reach near-optimal solutions that can be accepted as a feasible solution.

Meta-heuristic Algorithms

These algorithms are used to solve large problems or multi-objective problems. They are based on randomness rather than organized search, so they can reach search spaces that can not be reached by any other algorithms. Thus, optimal or near-optimal solutions can be found easily. The most popular algorithms are Genetic Algorithms and Simulated Annealing.

Applications of Assembly Lines

1- Automotive Industry

2- Home Appliance

3- Electronics

4- Furniture